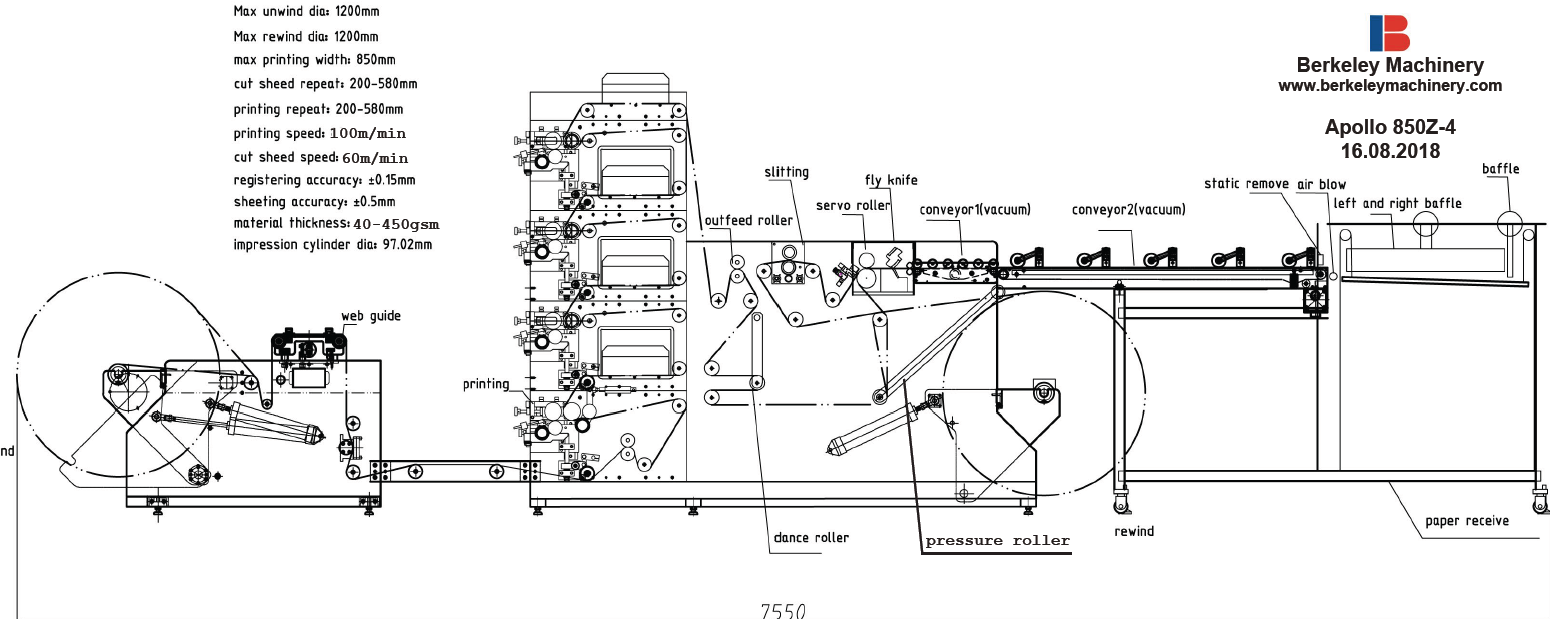

Apollo 850Z-4 Color

Ref: BM00536

Tooling:

Includes 3 sets of print cylinders 4 x 12”, 4 x 14”, 4 x 16”

Includes 4 anilox rollers: 1 x 400lpi, 1 x 500lpi, 2 x 650lpi

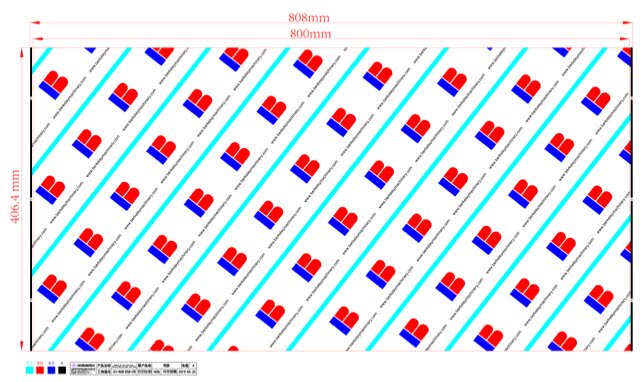

Web Width: 850mm

Printing width: 840mm

Gearing: 1/8"

Dimensions: 5070 x 2000 x 3000mm (L x W x H)

Material: 30gsm – 250gsm

1 x Unwind unit to take reels of 1200mm dia. on pneumatic shaft of 76mm or 152mm dia. with auto tension control and automatic hydraulic reel power lift for loading of heavy reels

1 x Infeed unit to control length and accurate feeding of variable materials, allowing for a range of materials from 20 microns to 350 microns. Thicker materials can be run subject to testing for a variety of industrial products

1 x Register/auto tension control. This is an independent electronic control system which gives infinite control of the tension and allows for the print units to produce excellent print quality

1 x Electronic web guide with electronic sensing to adjust the material accurately through the print units, press and converting process stations

4 x Variable flexographic print units to print from 8" to 20" circumference with manual 360° registration. Each unit can be individually disengaged if required. The print unit has a unique design to allow for variation of different print materials to run through the print units without exerting pressure on the drive gears. Therefore, alleviating any possible mechanical pressure through the print units to avoid bar or gear marks. The user friendly adjustable platform and tool-less assembly system for quick change of anilox and print cylinders make the press highly productive when changing from one job to another. The press comes with a motorised control for the continuous running of the anilox and metering roller when water based inks are used. This is to stop the drying of water based inks on the anilox and plate cylinder when the print cylinder is disengaged. Our new print cylinders are designed with a print sleeve, which is locked on a solid 50mm dia. shaft to provide excellent stability and cost savings to manufacture further print cylinders for client’s requirements.

4 x IR Drying Units thermostatically controlled for drying of water based or solvent inks

1 x Independent electronic tension control for rewinding

1 x Rewind unit to take reels of 1200mm dia. on pneumatic shaft of 76mm or 152mm dia. with auto tension control and automatic hydraulic reel power lift for loading of heavy reels

1 x Special Plate Mounter with optical magnifier. This is a table top plate mounter which has a viewing magnifier and a mounting system to produce perfect mounted plates for accurate and excellent print results when mounted on the print units

1 x Fly knife Sheeter to cut to any size

1 x Slitting unit including 4 knives

1 x Conveyor and deep pile stacker

1 x Video Inspection Unit

All helical gears on main drive. The helical drive gears are designed with a special pitch to allow for a perfect continuous drive and print results without any backlash which, in turn, enables very fine print to be produced … this is a unique feature and results in print results which exceed most printers expectations

3 sets of print cylinders included: 4 x 12”, 4 x 14”, 4 x 16”

1 set of ceramic anilox rollers: 1 x 400lpi, 1 x 500lpi, 2 x 650lpi

Power:

8.5kw main drive motor

1.6kw per IR drying unit

Drive Speed: 150m/minute

Converting Speed: 70-120/minute, depending on job being converted and conditions