Apollo ICM

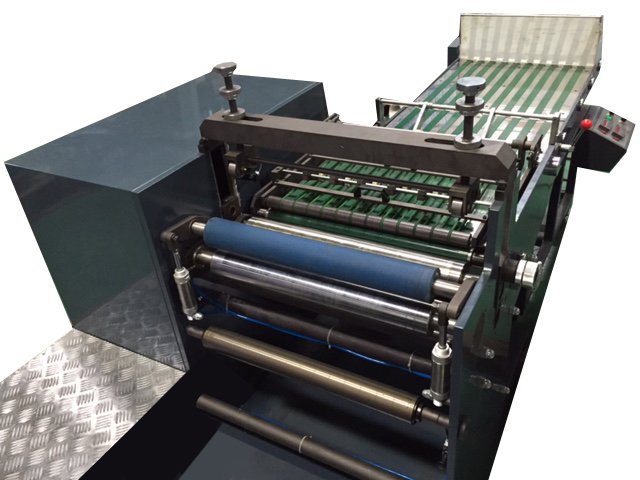

Industrial Converting Machine

The Apollo ICM Industrial Converting machine can be specifically made to convert special products and ca be custom-made to your requirements . The machine has the option to include several Reel Unwinds and Die Stations. It can also be ideal for pharmaceutical products etc.

The Apollo ICM can also integrate our LATEST SpeedMax Flat Bed Die-Cutting unit, which die cuts as fast as a Full Rotary Die-Cutting unit (for Offline Digitally Printed Material).

Web widths: 550mm, 610mm

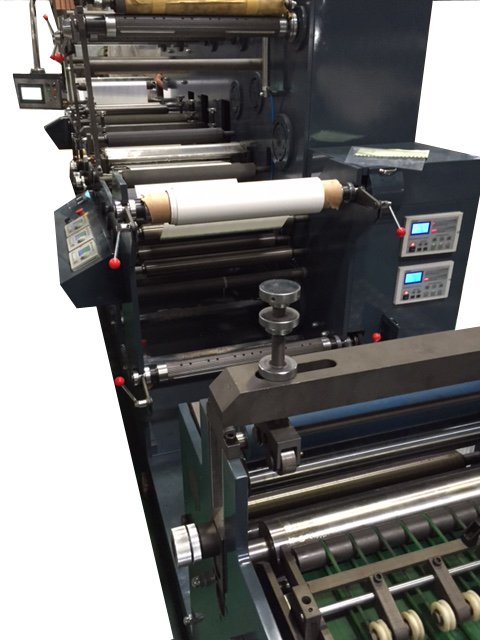

1 x Unwind unit with twin support frame, without power lift, to take reels up to 800mm dia. on 76mm

2 x Unwind cantilever units to take 500mm dia. rolls with pneumatic shaft of 76mm

3 x Tension controls, to operate each unwind cantilever units

3 x Floating shaft web guide for accurate converting and slitting

1 x 3 format draw rollers for keeping accurate web path

1 x Splicing table

1 x Sideway adjustment

3 x Lamination stations with 3 lamination reel shafts

3 x Die cutting units and matrix rewind for production of plain labels from 7” (177.8mm) – 24” (610mm) repeat / 1/8” pitch

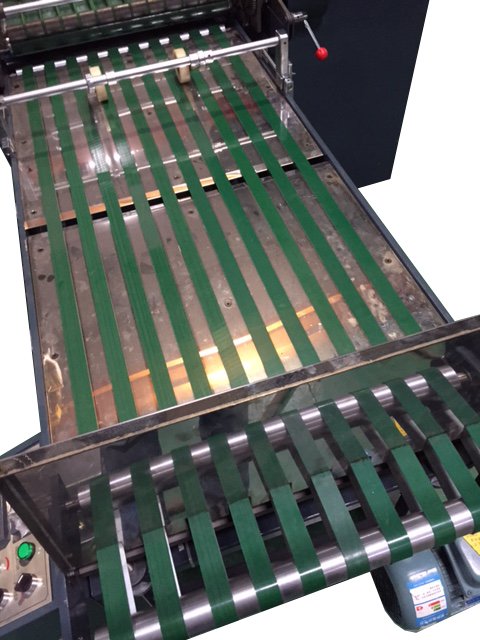

1 x Slitting station with quick change rotary slitting blades

1 x 3 cantilever duplex pneumatic product rewind shafts to rewind up to 500mm reels, the position of the rewind product shafts would be geometrically designed so that the rewinding of the final products are able to be rewound when multi-ply layers are converted so that if the requirement of removing the 1 layer for purpose of the final product, either rewind shaft can be used to meet the customer’s requirements. 1size of shafts included.

1 x Trim extraction unit included as a standard feature

1 x Motor with drive

1 x Automatic operator control unit for speed, length and label count

OPTIONS:

1 x Lay-on roller for 1 rewind shaft to rewind material without creasing

1 x Hydraulic jack pressure gauge for die station (1 set of 2)1 x Sheeting conveyor to output cut sheets from 2nd or 3rd die station

- Minimum cutting width 10mm

- Cutting precision +(-) 0.2mm

- Slitting speed, depending on material, between 80-120m/min.

- Die cutting speed, depending on design, between 80-120m/min.

- Dimensions 4500mm (L) x 1000mm (W) x 1200mm (H)

- Weight 3800kg

- Power supply 380 volts, 3 phase, 50Hz

- Power consumption 4.5kw

Testimonial

"I wanted to let you know that your Apollo 610 is still running faultlessly and very efficient. We have several new rotary machines but still turn to your machine for high running projects. Just wanted to pass on the good news” - James Sores. SOMO.TEC GMBH. Germany.