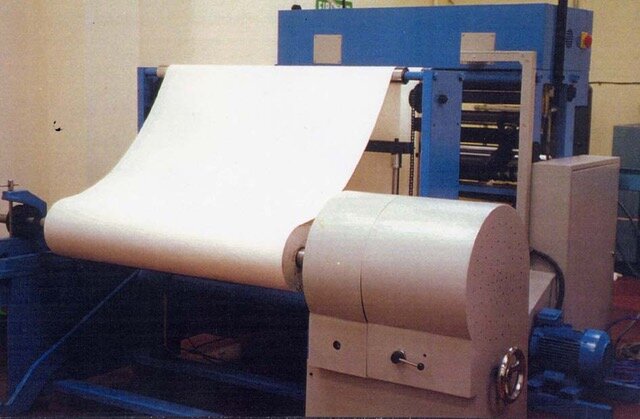

The Autocut SMR

The AutoCut SMR is a semi automated paper roll converting machine to produce small roll products for thermal printers and specialised industrial printers. This machine can also manufacture a wide range of roll products for the consumer industry. The machine is designed and built to a solid construction using international components.

The Autocut SMR900

Web width: 900mm

Unwind dia: 1250mm x 70mm, 76mm or 152mm core on pneumatic expanding shafts on reel stands made from 45mm cast iron. A cast iron cross brace frame of 100mm to support both side frames.

Speed: Up to 500m per minute through digital drive and P.L.C. control panel. For small roll production the speed is normally reduced by the operator through a user-friendly operating system.

Maximum rewind dia: 150mm for automatic ejection.

Maximum rewind dia: 300mm for manual ejection.

Minimum rewind dia: 10mm for automatic ejection.

Minimum core dia: 12mm O.D. Other sizes can be supplied

Substrate: 35gsm to 100gsm. Heavier materials have been successfully tested.

Drive: 15kw motor

Brake: Magnetic particle brake with infinite control to a digital drive and linked to the main control panel.

Slitting system: Quick change, user friendly scissor type slitting system, with 24 sets of rotary cutters with holders top and bottom. Minimum slitter width 17mm.

Tension: Automatic web tension system by dancer roll control and assisted by guide rollers.

Rewind: Surface type rewind system and one spreader roll before rewinding.

Gluing unit: Automatic gluing system for sealing of the finished rolls.

The Autocut SMR1200

Web width: 1200mm

Unwind dia: 1250mm x 70mm, 76mm or 152mm core on pneumatic expanding shafts on reel stands made from 45mm cast iron. A cast iron cross brace frame of 100mm to support both side frames.

Speed: Up to 500m per minute through digital drive and P.L.C. control panel. For small roll production the speed is normally reduced by the operator through a user-friendly operating system.

Maximum rewind dia: 150mm for automatic ejection.

Maximum rewind dia: 300mm for manual ejection.

Minimum rewind dia: 10mm for automatic ejection.

Minimum core dia: 12mm O.D. Other sizes can be supplied

Substrate: 35gsm to 100gsm. Heavier materials have been successfully tested.

Drive: 15kw motor

Brake: Magnetic particle brake with infinite control to a digital drive and linked to the main control panel.

Slitting system: Quick change, user friendly scissor type slitting system, with 24 sets of rotary cutters with holders top and bottom. Minimum slitter width 17mm.

Tension: Automatic web tension system by dancer roll control and assisted by guide rollers.

Rewind: Surface type rewind system and one spreader roll before rewinding.

Gluing unit: Automatic gluing system for sealing of the finished rolls.

Following features included:

a) Automatic vibrating core loading of cores onto the appropriate shaft

b) Automatic shaft loading onto the rewinding bed, after each manufacturing cycle

c) Automatic finished reel ejection system, to eject the finished rolls automatically, which is designed to push rolls up to 150mm dia. onto a conveyor

d) Automatic linear cutting system, which cuts the tail of the finished roll

e) Rider rollers automatically controlled during the process of the automated converting

f) Automatic pressing of paper onto the core, when the new cycle re-starts

g) Complete bottom cutter shaft assembly for one size

h) Conveyor to take finished rolls to packing line, including a pneumatic roll separation device

i) Further conveyor to take the finished rolls to a packing table, where a packer can load the finished rolls into a box

j) Final packing process of shrink wrapping the rolls and feeding into a loading bin

k) Two rewind shafts for I.D. 12.7mm and one other size will be supplied with the machine